I am a

student

institution

career professional

I need help with

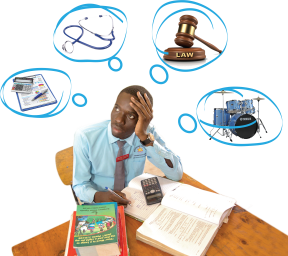

Career Selection & Planning

Find your best-fit career, stream, course or college through advanced assessments and expert guidance.

college applications

Get admits from your dream colleges through end-to-end applications guidance for overseas and liberal arts universities.

I am interested in

Career Development Programs

State-of-the-art career assessments, expert guidance, and more to help students plan their career paths.

Career Advancement Programs

Expert-led MUN training programs, inspirational career talks and more to help students get that added edge.

I am interested in

Getting Certified (ICCC)

Become an International Certified Career Coach through a multi-level credentialing program by Mindler & CDA (USA).

Partnering with Mindler

Expand and grow your career counselling practice by leveraging the full force of Mindler’s career guidance platform.

Ready to discover your perfect career?

Enter your email id to take the Orientation Style test for free.

CAREER COUNSELLING PROGRAMS

Class 8-9

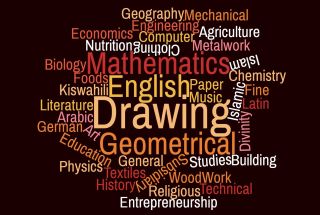

Stream & Subject SelectionAdvanced assessment & personalised guidance to help you select the perfect stream and subjects that align you to the right careers.

Class 10-12

Career Selection & PlanningExpert guidance & 5-dimensional assessment to help you discover your perfect career and choose the right course and college.

Graduates

Career Selection & Development5-dimensional assessment & superior guidance to help you discover your perfect career and choose the best next step.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Ready to pave your way to your dream college?

Leave your details below and we will get in touch shortly.

COLLEGE APPLICATION PROGRAMS

Overseas Application

End-to-end overseas admissions guidance to help you build the perfect applications for your target universities.

Liberal Arts Application

Comprehensive guidance and personalised application development for admissions to Liberal Arts programs.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Ready to give students the best of career guidance?

Leave your details below and we will get in touch shortly.

Career Development Programs

Career Development &

Planning Ecosystem

State-of-the-art assessment & end-to-end career guidance to help students discover their perfect career.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Ready to give your students the added edge?

Leave your details below and we will get in touch shortly.

Career Advancement Programs

MUN Training Program

Expert-led training and comprehensive guidance sessions to help students excel at MUN conferences.

Mindler Talks

Career awareness and inspirational talks for students with professionals who have achieved success in their fields.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Ready to upgrade your career counselling skills?

Enter your email id to start your ICCC application.

Getting Certified (ICCC)

International Certified

Career Coach (ICCC)

A 3-month program with emphasis on global practices, experiential learning & career guidance tools.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Ready to grow as a counsellor?

Leave your details below and we will get in touch shortly.

Partnering with Mindler

Mindler Partner Program

World-class career assessment platform & tools to help you scale up your career counselling practice.

Thank you for contacting us!

One of our team members will respond in 2 working days to resolve your query. If your query is urgent, you can alternatively call our career helpline.

Breaking News

- Flexible Remote Work Opportunity for University Students: Earn $100–$250 Per Month ...Read More

- Ministry of Education and Sports Azerbaijan Government Scholarships For 2025-2026 Academic Year ...Read More

- Government Sponsorship Undergraduate Admission Lists 2025-26 for Makerere University ...Read More

- Ministry of Education And Sports: Egyptian Government Scholarships 2025-2026 Academic Year ...Read More

- Ground Breaker Full Scholarship for girls to study Software Engineering 2025 July Intake ...Read More

- Tony Elumelu Foundation Entrepreneurship Programme (TEEP) 2025 for young African Entrepreneurs ...Read More

- DESIGNING FUTURES 2050 International Design Competition 2025 (€15,000 prize) ...Read More

- Ground Breaker Full time Scholarship for girls to study Software Engineering 2025 Intake ...Read More

- Ministry of Education And Sports Algerian Vocational Training Scholarships for 2024-2025 AY ...Read More

- Ministry of Education and Sports Advert for the Algerian Government Scholarships for 2024-2025 ...Read More

Welder

Use hand-welding or flame-cutting equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

Add to FavouritesUse hand-welding or flame-cutting equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

Daily Tasks / Routine Activities

1. Weld components in flat, vertical, or overhead positions.

2. Operate safety equipment and use safe work habits.

3. Lay out, position, align, and secure parts and assemblies prior to assembly, using straightedges, combination squares, calipers, and rulers.

4. Examine workpieces for defects and measure workpieces with straightedges or templates to ensure conformance with specifications.

5. Recognize, set up, and operate hand and power tools common to the welding trade, such as shielded metal arc and gas metal arc welding equipment.

6. Weld separately or in combination, using aluminum, stainless steel, cast iron, and other alloys.

7. Clamp, hold, tack-weld, heat-bend, grind or bolt component parts to obtain required configurations and positions for welding.

8. Select and install torches, torch tips, filler rods, and flux, according to welding chart specifications or types and thicknesses of metals.

9. Ignite torches or start power supplies and strike arcs by touching electrodes to metals being welded, completing electrical circuits.

10. Connect and turn regulator valves to activate and adjust gas flow and pressure so that desired flames are obtained.

Key knowledge areas

1. Production and Processing — Knowledge of raw materials, production processes, quality control, costs, and other techniques for maximizing the effective manufacture and distribution of goods.

2. Design — Knowledge of design techniques, tools, and principles involved in production of precision technical plans, blueprints, drawings, and models.

3. Administration and Management — Knowledge of business and management principles involved in strategic planning, resource allocation, human resources modeling, leadership technique, production methods, and coordination of people and resources.

4. Mechanical — Knowledge of machines and tools, including their designs, uses, repair, and maintenance.

5. Mathematics — Knowledge of arithmetic, algebra, geometry, calculus, statistics, and their applications.

6. Customer and Personal Service — Knowledge of principles and processes for providing customer and personal services. This includes customer needs assessment, meeting quality standards for services, and evaluation of customer satisfaction.

7. English Language — Knowledge of the structure and content of the English language including the meaning and spelling of words, rules of composition, and grammar.

8. Engineering and Technology — Knowledge of the practical application of engineering science and technology. This includes applying principles, techniques, procedures, and equipment to the design and production of various goods and services.

Skills

1. Critical Thinking — Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions or approaches to problems.

2. Operation and Control — Controlling operations of equipment or systems.

3. Monitoring — Monitoring/Assessing performance of yourself, other individuals, or organizations to make improvements or take corrective action.

4. Reading Comprehension — Understanding written sentences and paragraphs in work related documents.

-

Ministry of Education And Sports: Egyptian Government Scholarships 2025-2026 Academic Year

Full Scholarship

Ministry of Education And Sports: Egyptian Government Scholarships 2025-2026 Academic Year

Full Scholarship

Know more -

Priscilla Namwenje, A Ugandan Architect wins LafargeHolcim Next Generation Top Prize

Connective Infrastructure

Priscilla Namwenje, A Ugandan Architect wins LafargeHolcim Next Generation Top Prize

Connective Infrastructure

Know more -

TU Delft Summer School Scholarships 2024 for Students (Fully Funded to Delft, Netherlands)

Summer School Program for students doing Architecture or Urban Planning

Know more -

Enabel and PSFU Work Readiness Program for recent graduates from Uganda

Connecting graduates to hundreds of Employers

Enabel and PSFU Work Readiness Program for recent graduates from Uganda

Connecting graduates to hundreds of Employers

Know more -

Makerere University invites private undergraduate applicants for academic year 2017-2018

Private sponsorship scheme applications for undergraduate are open

Makerere University invites private undergraduate applicants for academic year 2017-2018

Private sponsorship scheme applications for undergraduate are open

Know more

Draw Inspiration from time tested individuals

-

Meet Welline Rebecca, a 22 year old who repairs welding transformers

Meet Welline Rebecca, a 22 year old who repairs welding transformers

Watch Interview -

Ruth Nabatanzi thrives as a metal fabricator

Ruth Nabatanzi thrives as a metal fabricator

Watch Interview

Careers that are in the same career field as Welder

-

Architect

Know more

Architect

Know more -

Civil Engineer

Know more

Civil Engineer

Know more -

Interior Designer

Know more

Interior Designer

Know more - Landscape Architect Know more

-

Surveyor

Know more

Surveyor

Know more -

Construction manager

Know more

Construction manager

Know more -

Water engineer

Know more

Water engineer

Know more -

Site engineer

Know more

Site engineer

Know more -

Plumber

Know more

Plumber

Know more -

Carpenter

Know more

Carpenter

Know more - Electrician Know more

-

Welder

Know more

Welder

Know more -

Construction Manager

Know more

Construction Manager

Know more -

Cost Estimator

Know more

Cost Estimator

Know more -

Geodetic Surveyor

Know more

Geodetic Surveyor

Know more -

Architectural and Civil Drafter

Know more

Architectural and Civil Drafter

Know more -

Architectural Drafter

Know more

Architectural Drafter

Know more -

Civil Drafter Know more

-

Civil Engineering Technician

Know more

Civil Engineering Technician

Know more -

Surveying and Mapping Technician

Know more

Surveying and Mapping Technician

Know more -

Surveying Technician

Know more

Surveying Technician

Know more -

Mapping Technician

Know more

Mapping Technician

Know more -

Pest Control Worker

Know more

Pest Control Worker

Know more -

Tree Trimmer and Pruner

Know more

Tree Trimmer and Pruner

Know more -

First-Line Supervisors of Construction Trades and Extraction Worker

Know more

First-Line Supervisors of Construction Trades and Extraction Worker

Know more -

Solar Energy Installation Manager

Know more

Solar Energy Installation Manager

Know more -

Boilermaker

Know more

Boilermaker

Know more -

Brickmason and Blockmason (Builder)

Know more

Brickmason and Blockmason (Builder)

Know more -

Stone Mason (Builder)

Know more

Stone Mason (Builder)

Know more -

Construction Carpenter

Know more

Construction Carpenter

Know more -

Rough Carpenter

Know more

Rough Carpenter

Know more -

Carpet Installer

Know more

Carpet Installer

Know more -

Floor Layer, Except Carpet, Wood, and Hard Tiles

Know more

Floor Layer, Except Carpet, Wood, and Hard Tiles

Know more -

Floor Sander and Finisher

Know more

Floor Sander and Finisher

Know more -

Tile and Marble Setter

Know more

Tile and Marble Setter

Know more -

Cement Masons and Concrete Finisher

Know more

Cement Masons and Concrete Finisher

Know more -

Terrazzo Worker and Finisher

Know more

Terrazzo Worker and Finisher

Know more -

Construction Laborer

Know more

Construction Laborer

Know more -

Paving, Surfacing, and Tamping Equipment Operator

Know more

Paving, Surfacing, and Tamping Equipment Operator

Know more -

Pile-Driver Operator

Know more

Pile-Driver Operator

Know more -

Operating Engineers and Other Construction Equipment Operator

Know more

Operating Engineers and Other Construction Equipment Operator

Know more -

Drywall and Ceiling Tile Installer

Know more

Drywall and Ceiling Tile Installer

Know more -

Taper

Know more

Taper

Know more -

Glazier

Know more

Glazier

Know more -

Insulation Worker, Floor, Ceiling, and Wall

Know more

Insulation Worker, Floor, Ceiling, and Wall

Know more -

Insulation Worker, Mechanical

Know more

Insulation Worker, Mechanical

Know more -

Painter, Construction and Maintenance

Know more

Painter, Construction and Maintenance

Know more - Paperhanger Know more

-

Pipelayer

Know more

Pipelayer

Know more -

Plumber, Pipefitter, and Steamfitter

Know more

Plumber, Pipefitter, and Steamfitter

Know more -

Pipe Fitter and Steamfitter

Know more

Pipe Fitter and Steamfitter

Know more -

Plasterer and Stucco Mason

Know more

Plasterer and Stucco Mason

Know more -

Reinforcing Iron and Rebar Worker

Know more

Reinforcing Iron and Rebar Worker

Know more -

Roofer

Know more

Roofer

Know more -

Sheet Metal Worker

Know more

Sheet Metal Worker

Know more -

Structural Iron and Steel Worker

Know more

Structural Iron and Steel Worker

Know more -

Solar Photovoltaic Installer

Know more

Solar Photovoltaic Installer

Know more -

Helpers--Brickmasons, Blockmasons, Stonemasons, and Tile and Marble Setter

Know more

Helpers--Brickmasons, Blockmasons, Stonemasons, and Tile and Marble Setter

Know more -

Helpers--Carpenter

Know more

Helpers--Carpenter

Know more -

Helpers--Electrician

Know more

Helpers--Electrician

Know more -

Helpers--Painters, Paperhangers, Plasterers, and Stucco Mason

Know more

Helpers--Painters, Paperhangers, Plasterers, and Stucco Mason

Know more -

Helpers-Pipelayers, Plumbers, Pipefitters, and Steamfitter

Know more

Helpers-Pipelayers, Plumbers, Pipefitters, and Steamfitter

Know more -

Helpers--Roofer

Know more

Helpers--Roofer

Know more -

Construction and Building Inspector

Know more

Construction and Building Inspector

Know more -

Elevator Installer and Repairer

Know more

Elevator Installer and Repairer

Know more -

Hazardous Materials Removal Worker

Know more

Hazardous Materials Removal Worker

Know more - Rail-Track Laying and Maintenance Equipment Operator Know more

-

Septic Tank Servicer and Sewer Pipe Cleaner

Know more

Septic Tank Servicer and Sewer Pipe Cleaner

Know more -

Segmental Paver

Know more

Segmental Paver

Know more -

Solar Thermal Installer and Technician

Know more

Solar Thermal Installer and Technician

Know more -

Weatherization Installers and Technician

Know more

Weatherization Installers and Technician

Know more -

Derrick Operator, Oil and Gas

Know more

Derrick Operator, Oil and Gas

Know more -

Rotary Drill Operator, Oil and Gas

Know more

Rotary Drill Operator, Oil and Gas

Know more -

Service Unit Operator, Oil, Gas, and Mining

Know more

Service Unit Operator, Oil, Gas, and Mining

Know more -

Earth Driller, Except Oil and Gas

Know more

Earth Driller, Except Oil and Gas

Know more -

Explosives Worker, Ordnance Handling Expert, and Blaster

Know more

Explosives Worker, Ordnance Handling Expert, and Blaster

Know more -

Continuous Mining Machine Operator

Know more

Continuous Mining Machine Operator

Know more -

Mine Cutting and Channeling Machine Operator

Know more

Mine Cutting and Channeling Machine Operator

Know more -

Rock Splitter, Quarry

Know more

Rock Splitter, Quarry

Know more -

Roof Bolter, Mining

Know more

Roof Bolter, Mining

Know more -

Roustabout, Oil and Gas

Know more

Roustabout, Oil and Gas

Know more -

Helpers--Extraction Worker

Know more

Helpers--Extraction Worker

Know more -

Tire Repairers and Changer

Know more

Tire Repairers and Changer

Know more -

Mechanical Door Repairer

Know more

Mechanical Door Repairer

Know more -

Control and Valve Installers and Repairers, Except Mechanical Door

Know more

Control and Valve Installers and Repairers, Except Mechanical Door

Know more -

Heating, Air Conditioning, and Refrigeration Mechanics and Installer

Know more

Heating, Air Conditioning, and Refrigeration Mechanics and Installer

Know more -

Heating and Air Conditioning Mechanics and Installer

Know more

Heating and Air Conditioning Mechanics and Installer

Know more -

Maintenance Workers, Machinery

Know more

Maintenance Workers, Machinery

Know more -

Millwright

Know more

Millwright

Know more -

Refractory Materials Repairers, Except Brickmason

Know more

Refractory Materials Repairers, Except Brickmason

Know more - Coin, Vending, and Amusement Machine Servicer and Repairer Know more

-

Locksmith and Safe Repairer

Know more

Locksmith and Safe Repairer

Know more -

Manufactured Building and Mobile Home Installer

Know more

Manufactured Building and Mobile Home Installer

Know more -

Signal and Track Switch Repairer

Know more

Signal and Track Switch Repairer

Know more - Engine and Other Machine Assembler Know more

-

Power Plant Operator

Know more

Power Plant Operator

Know more -

Conveyor Operator and Tender

Know more

Conveyor Operator and Tender

Know more -

Crane and Tower Operator

Know more

Crane and Tower Operator

Know more -

Dredge Operator

Know more

Dredge Operator

Know more -

Excavating and Loading Machine and Dragline Operator

Know more

Excavating and Loading Machine and Dragline Operator

Know more -

Loading Machine Operator, Underground Mining

Know more

Loading Machine Operator, Underground Mining

Know more -

Security and Fire Alarm Systems Installer

Know more

Security and Fire Alarm Systems Installer

Know more

Online Training in Architecture and Construction

Trending Opportunities

Latest Jobs Corner

-

Several No Experience Relationship Officer – Community Banking Job Opportunities – Pride Bank

Posted: Posted Thu, 04 Dec 2025 15:20:49 +0000 -

Several Relationship Officer – Agribusiness Jobs – Pride Bank

Posted: Posted Thu, 04 Dec 2025 15:10:38 +0000 -

Several No Experience Relationship Officer – Group Banking Job Placements – Pride Bank

Posted: Posted Thu, 04 Dec 2025 15:00:23 +0000 -

Manager Payments and Clearing Jobs – I&M; Bank Uganda

Posted: Posted Thu, 04 Dec 2025 14:50:07 +0000 -

Business Development & Partnerships Associate Jobs – Sun King

Posted: Posted Thu, 04 Dec 2025 14:39:56 +0000 -

Finance Manager Jobs – Cerba Lancet Uganda

Posted: Posted Thu, 04 Dec 2025 14:29:46 +0000 -

Quality Controller Jobs – BondRich Advisory Group

Posted: Posted Thu, 04 Dec 2025 14:19:38 +0000 -

Business Performance Manager Jobs – Human Capital Business Solutions

Posted: Posted Thu, 04 Dec 2025 14:09:24 +0000 -

Manager Digital Lending Jobs – Housing Finance Bank

Posted: Posted Thu, 04 Dec 2025 13:59:09 +0000 -

Forensics and Investigations Supervisor Jobs – Bayport Financial Services Uganda

Posted: Posted Thu, 04 Dec 2025 11:00:42 +0000

Advertisement

Trending Opportunities

Advertisement

Popular Careers

-

Civil Engineer

30070 Views -

Actor

24288 Views -

Flight attendant

22295 Views -

Fashion Designer

20563 Views -

Pilot and flight engineer

19184 Views