Breaking News

- Flexible Remote Work Opportunity for University Students: Earn $100–$250 Per Month ...Read More

- Ministry of Education and Sports Azerbaijan Government Scholarships For 2025-2026 Academic Year ...Read More

- Government Sponsorship Undergraduate Admission Lists 2025-26 for Makerere University ...Read More

- Ministry of Education And Sports: Egyptian Government Scholarships 2025-2026 Academic Year ...Read More

- Ground Breaker Full Scholarship for girls to study Software Engineering 2025 July Intake ...Read More

- Tony Elumelu Foundation Entrepreneurship Programme (TEEP) 2025 for young African Entrepreneurs ...Read More

- DESIGNING FUTURES 2050 International Design Competition 2025 (€15,000 prize) ...Read More

- Ground Breaker Full time Scholarship for girls to study Software Engineering 2025 Intake ...Read More

- Ministry of Education And Sports Algerian Vocational Training Scholarships for 2024-2025 AY ...Read More

- Ministry of Education and Sports Advert for the Algerian Government Scholarships for 2024-2025 ...Read More

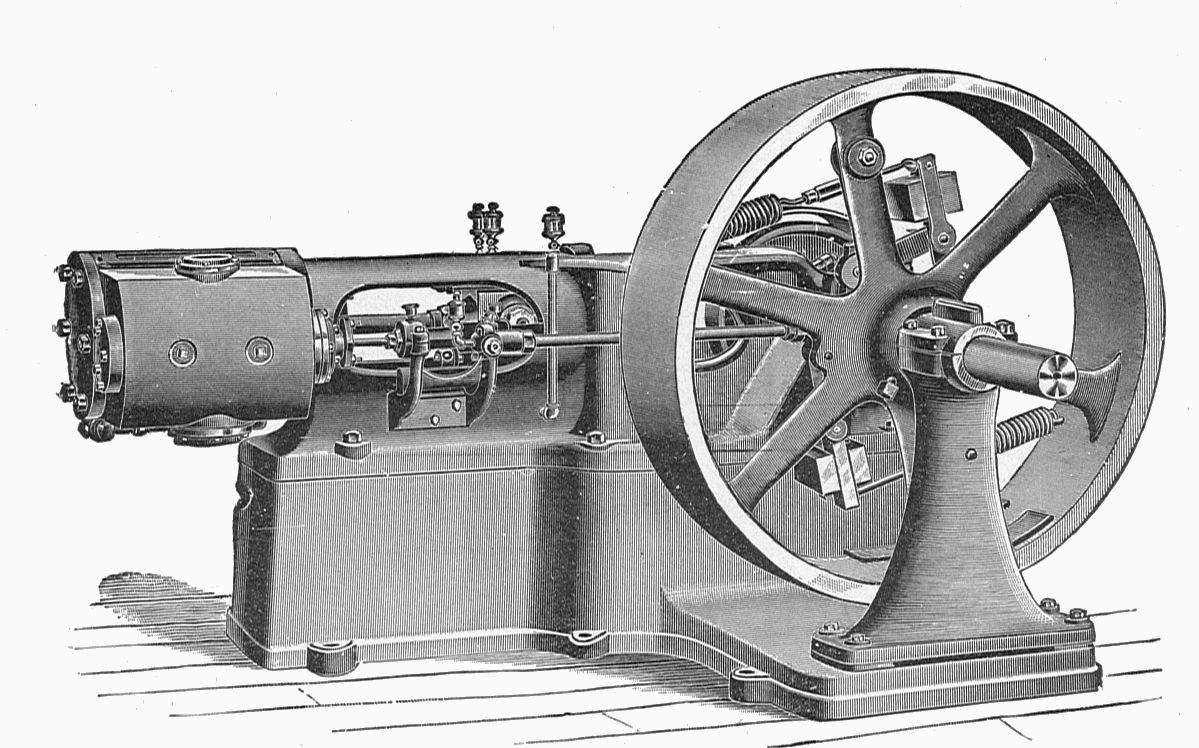

Makerere reverts to steam engine for more energy

For hundreds of years, scientists have experimented with various methods of generating energy. These have included steam, solar and hydrocarbon fuel. As MOSES TALEMWA found, scientists at Makerere University are engaged in a promising study into how to obtain energy from steam.

On a hot morning last week, I arrived at Makerere’s College of Engineering, Design, Art and Technology (Cedat) to find two technicians working around a boiler-like contraption that soon started spewing a grayish smoke.

Edwin Lukubira and Rogers Mubiru are part of a four-member team behind what is tentatively known as the Mak Steam engine, now under study. The other members are Dr John Baptist Kirabira (as principal investigator) and Andrew Ayor (project coordinator).

According to Ayor, a mechanical engineering graduate, the idea behind the system is use of super-heated charge of steam to generate power.

“This technology was used in the design of trains and steam ships back in the 1800s, but further research in the area was abandoned in 20th century on the discovery of fuel [hydrocarbons],” Ayor said. “We are only resuming this research now, because we believe it is environmentally-friendly and cost-effective.”

What Ayor is talking about relates to efforts to generate energy from boiled water, going back over 1,000 years. The research only gained traction in 1781, when Scottish researcher James Watt patented a steam engine that produced continuous rotary motion. Watt’s ten-horsepower engines enabled a wide range of manufacturing machinery to be powered.

By 1883, engines that could provide 10,000hp had become feasible. Studies show that atmospheric engines by Watt were large compared to the amount of power they produced, but later designs of high-pressure steam engines became light enough to be applied to vehicles such as traction engines and the railway locomotives and industries wherever water and coal or wood fuel could be obtained.

Dr John Baptist Kirabira, the steam engine principal coordinator (squatting), observes the engine as the technician Edwin Lukubira gets it started

Later, Watt’s research was influential in the development of steam ships and rail systems, eventually giving way to fuel-powered engines, as they were adjudged more efficient in generating and transferring energy.

But Ayor and Kirabira insist that continued research into the use of steam could generate even more energy for use in other areas.

“Apart from its environmentally-friendly properties, steam develops a lot of energy quite quickly and is more affordable than hydrocarbons, making it possible for use in many areas,” Kirabira explained.

ORIGINS

According to Dr Kirabira, also head of Mechanical Engineering at Makerere University, development of the steam engine started in 2013, with the objective of finding ways of harnessing energy from steam for industrial use.

Ayor takes up the story by adding that the project, now under Centre for Technical Design and Development in Cedat, was the result of observations in the field.

“We found Edwin and Roger using the ordinary three stones to boil water for use in a mechanical garage, and we decided that we could develop the technology further,” Ayor says. “We have been developing the design to make it more efficient.”

The current setup, developed from a contraption similar to a charcoal-stove, now features a 2.5 litre water tank sitting atop a boiler (furnace), with an adjoining cylindrical container filled with used oil or other combustible materials such as maize husks.

The technicians light the furnace, which in turn heats the water to boiling temperature. The furnace is connected by a plug, made from mild steel of 6mm thickness. Once the water is heated, it is injected by a mixture of water and heat to create super-heated steam (dry steam).

“[After the water boils], we launch the engine with a turn of the ignition, which powers the piston to create the energy to drive the flywheel, which can be connected to a water pump or mill,” Ayor explains.

Once the engine is launched, the steam drives the process continuously on its own, generating enough energy to drive machines. Ayor adds that studies into the machine have shown that the engine can run between 3500rpm (revolutions per minute) and 5,000rpm at idling stage.

Lukubira added that they had found that with just 2.5 litres of water, they could power any machine for nearly two hours, before needing a refill.

“The beauty of this engine is that apart from the back fire from the exhaust, it does not contaminate the environment in any way, since the steam generated is safe,” he says.

His colleague Mubiru believes that the engineers at Makerere are continuing to refine the engine and even the noise will eventually be eliminated.

To this, Kirabira and Ayor agree. For Ayor, who will soon involve some of his mechanical engineering students in the project, “the engine has so far been a proof of concept, that steam can be harnessed to create reusable energy at an affordable cost”.

Ayor has selected four third-year engineering students; Kassim Komakech, Charlene Kariisa, Ivan James Nyonyintono and Samuel Musisi to develop the mathematical models for a more refined design of the engine.

Dr Kirabira adds: “Once the modeling is done, we hope that we will develop a refined design that we can develop into a full-fledged engine model”.

Ayor adds that they will also work on determining appropriate materials for the development of the engine, to eliminate undesirable problems like smoke during the initial boiling of the water, noise and excess heating, which lead to energy losses.

APPLICATIONS

Just like the Kiira EV before it, the Mak Steam is being developed, with support from the Presidential Initiative for Science and Technology. Ayor believes that once developed the Mak Steam will have applications in agriculture.

“We are looking at applications in irrigation, mills, hullers and steam drying of such items as Mukene [silver cyprinid] and other fruits,” Ayor says.

However, he does not rule out other applications in powering vehicles or machines.

“We are still assessing how much energy the engine would be able to generate ... this is what would then inform us on the relevant applications,” Ayor adds.

The news of this engine is likely to excite another team of innovators at the Makerere University Agricultural Research Institute in Kabanyoro, who are working on improving the MV Mulimi – a vehicle aimed at farmers.

According to a member of the team developing MV Mulimi, Dr Nicholas Kiggundu, they are looking to develop an engine that will generate as much energy as possible, while remaining affordable.

“Our vehicle is designed to be able to assist in irrigation, shelling of maize and pumping water to a height,” Dr Kiggundu explained. “Farmers are also telling us they would need a truck that also acts as a tipper.”

Ayor believes that whereas the MV Mulimi is powered by diesel, the Mak Steam engine is also able to carry out some of the same tasks.

Written by Moses Talemwa

Source theobserver

Top Courses Currently Admitting

-

Bachelor of Education (Secondary 2 Years)

Nkumba University

-

Bachelor of Business Statistics

Makerere University Business School

-

Diploma in Fashion & Retail Design

Limkokwing University

-

Diploma in Instuctor and Technical Teacher Education

Nakawa Vocational Training College

-

Bachelor of Engineering in Automotive and Power Engineering

Kyambogo University