Breaking News

- Flexible Remote Work Opportunity for University Students: Earn $100–$250 Per Month ...Read More

- Ministry of Education and Sports Azerbaijan Government Scholarships For 2025-2026 Academic Year ...Read More

- Government Sponsorship Undergraduate Admission Lists 2025-26 for Makerere University ...Read More

- Ministry of Education And Sports: Egyptian Government Scholarships 2025-2026 Academic Year ...Read More

- Ground Breaker Full Scholarship for girls to study Software Engineering 2025 July Intake ...Read More

- Tony Elumelu Foundation Entrepreneurship Programme (TEEP) 2025 for young African Entrepreneurs ...Read More

- DESIGNING FUTURES 2050 International Design Competition 2025 (€15,000 prize) ...Read More

- Ground Breaker Full time Scholarship for girls to study Software Engineering 2025 Intake ...Read More

- Ministry of Education And Sports Algerian Vocational Training Scholarships for 2024-2025 AY ...Read More

- Ministry of Education and Sports Advert for the Algerian Government Scholarships for 2024-2025 ...Read More

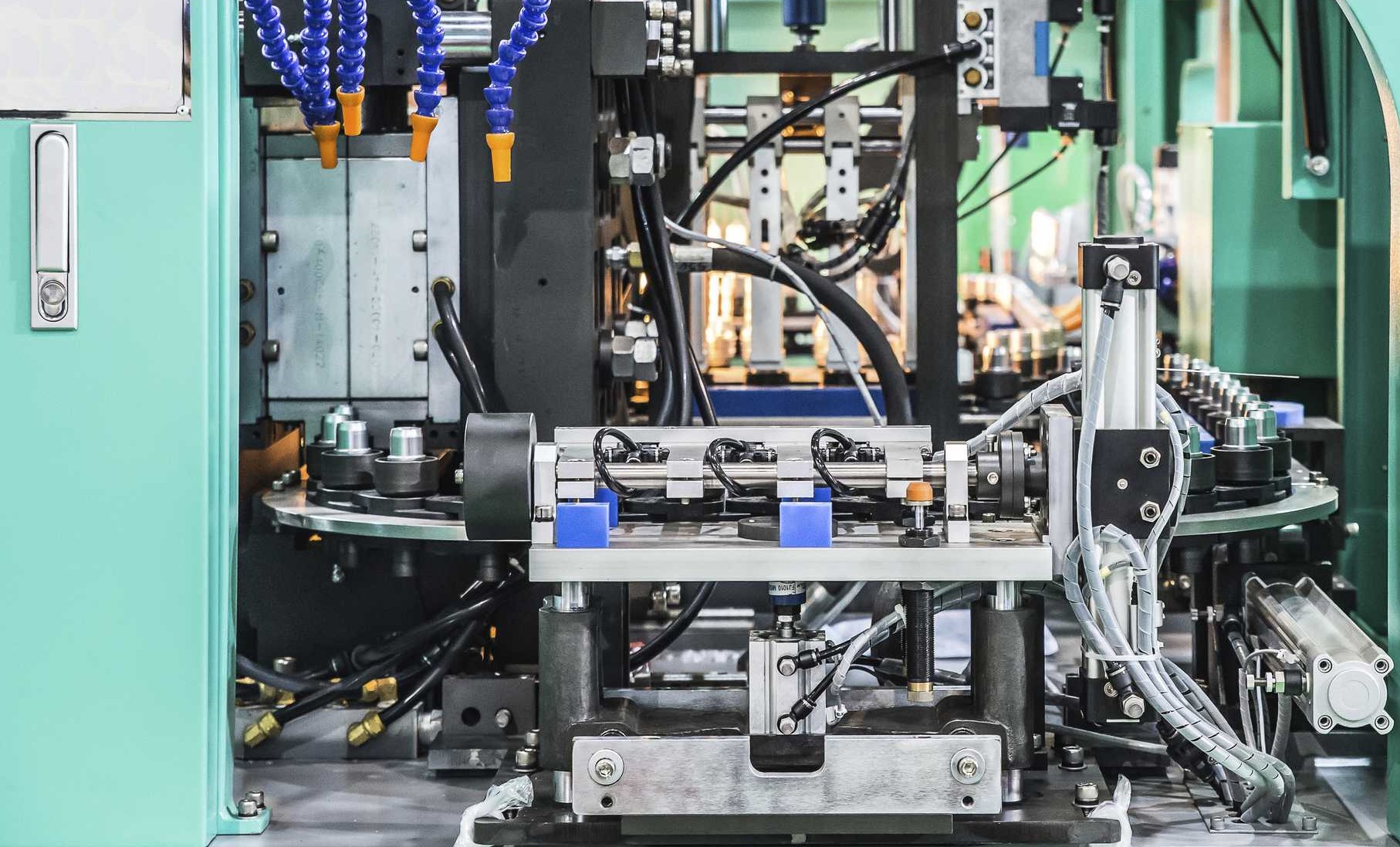

Manufacturing Careers

Rolling Machine Setters, Operator, and Tender, Metal and Plastic

Set up, operate, or tend machines to roll steel or plastic forming bends, beads, knurls, rolls, or plate or to flatten, temper, or reduce gauge of material.

Know MoreCutting, Punching, and Press Machine Setter, Operator, and Tenders, Metal and Plastic

Set up, operate, or tend machines to saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal or plastic material.

Know MoreDrilling and Boring Machine Tool Setters, Operator, and Tender, Metal and Plastic

Set up, operate, or tend drilling machines to drill, bore, ream, mill, or countersink metal or plastic work pieces.

Know MoreGrinding, Lapping, Polishing, and Buffing Machine Tool Setters, Operators, and Tender, Metal and Plastic

Set up, operate, or tend grinding and related tools that remove excess material or burrs from surfaces, sharpen edges or corners, or buff, hone, or polish metal or plastic work pieces.

Know MoreLathe and Turning Machine Tool Setters, Operator, and Tender, Metal and Plastic

Set up, operate, or tend lathe and turning machines to turn, bore, thread, form, or face metal or plastic materials, such as wire, rod, or bar stock.

Know MoreMilling and Planing Machine Setter, Operator, and Tender, Metal and Plastic

Set up, operate, or tend milling or planing machines to mill, plane, shape, groove, or profile metal or plastic work pieces.

Know MoreMachinist

Set up and operate a variety of machine tools to produce precision parts and instruments. Includes precision instrument makers who fabricate, modify, or repair mechanical instruments. May also fabricate and modify parts to make or repair machine tools or maintain industrial machines, applying knowledge of mechanics, mathematics, metal properties, layout, and machining procedures.

Know MoreMetal-Refining Furnace Operators and Tender

Operate or tend furnaces, such as gas, oil, coal, electric-arc or electric induction, open-hearth, or oxygen furnaces, to melt and refine metal before casting or to produce specified types of steel.

Know MorePourer and Caster, Metal

Operate hand-controlled mechanisms to pour and regulate the flow of molten metal into molds to produce castings or ingots.

Know MoreModel Maker, Metal and Plastic

Set up and operate machines, such as lathes, milling and engraving machines, and jig borers to make working models of metal or plastic objects. Includes template makers.

Know MorePatternmaker, Metal and Plastic

Lay out, machine, fit, and assemble castings and parts to metal or plastic foundry patterns, core boxes, or match plates.

Know MoreFoundry Mold and Coremaker

Make or form wax or sand cores or molds used in the production of metal castings in foundries.

Know MoreMolding, Coremaking, and Casting Machine Setter, Operator, and Tender, Metal and Plastic

Set up, operate, or tend metal or plastic molding, casting, or coremaking machines to mold or cast metal or thermoplastic parts or products.

Know MoreMultiple Machine Tool Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend more than one type of cutting or forming machine tool or robot.

Know MoreTool and Die Makers

Analyze specifications, lay out metal stock, set up and operate machine tools, and fit and assemble parts to make and repair dies, cutting tools, jigs, fixtures, gauges, and machinists' hand tools.

Know MoreWelder, Cutter, Solderer, and Brazer

Use hand-welding, flame-cutting, hand soldering, or brazing equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

Know MoreWelder, Cutters, and Welder Fitter

Use hand-welding or flame-cutting equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

Know MoreSolderer and Brazer

Braze or solder together components to assemble fabricated metal parts, using soldering iron, torch, or welding machine and flux.

Know MoreWelding, Soldering, and Brazing Machine Setters, Operators, and Tenders

Set up, operate, or tend welding, soldering, or brazing machines or robots that weld, braze, solder, or heat treat metal products, components, or assemblies. Includes workers who operate laser cutters or laser-beam machines.

Know MoreHeat Treating Equipment Setter, Operator, and Tender, Metal and Plastic

Set up, operate, or tend heating equipment, such as heat-treating furnaces, flame-hardening machines, induction machines, soaking pits, or vacuum equipment to temper, harden, anneal, or heat-treat metal or plastic objects.

Know More